DIDACTICS

Hydraulic test benches

Thanks to the experience, we have created an offer addressed to secondary and higher schools with a technical profile, as well as production plants associated with the specialty of machine drives. The offer includes the production of didactic test bebches used to conduct practical classes on hydraulic and pneumatic drives.

The stands are manufactured by us from scratch, and their configuration is strictly adapted to the customer's requirements. Depending on the needs, it is possible to prepare a design of benches with different levels of advancement: from the simplest versions enabling basic exercises, to very advanced versions presenting the principles of variable displacement pumps with various regulators, proportional control, programming principles and advanced measurement techniques. This allows for close adaptation to the level of knowledge of students or engineering staff of production plants.

The components of well-known and reputable manufacturers are used to build the stands, guaranteeing long-lasting and trouble-free operation. The modular design and power supply from the low voltage network allows for quick set-up between different operating schemes and easy installation in standard didactic rooms.

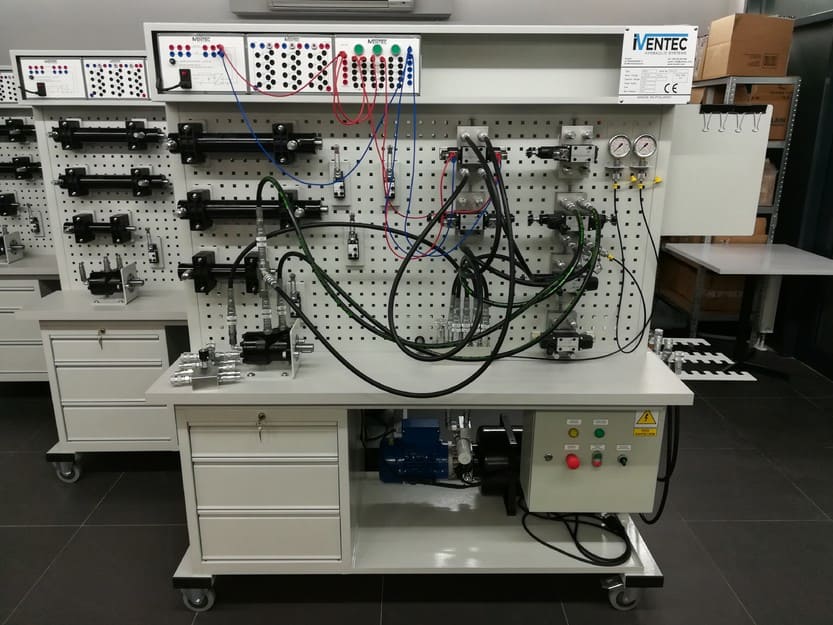

Test bench DMSD-01

Example configuration

- Mobile assembly table with a double-sided work area, equipped with a container with drawers, a panel for mounting electrical relays, a holder for hanging diagrams and a hanger for hydraulic hoses

- Hydraulic power supply with a pump with reduced noise level comparing to standard values, flow 8 l/min, electric motor 230 V, 50 Hz, 1,1 kW, pressure limiting valve and solenoid valve for quick pressure release from the system

- Electric control panel controlling the operation of the power supply with overload protection

- Power supply DC panel

- Panel with set of electric relays

- Panel with electrical switches

- 2 x manifold branching the pressure and return line with a built-in manual relief valve

- 1 x single acting cylinder with return spring

- 2 x double-acting cylinder

- 4 x electric limit switch

- 1 x orbital motor

- 2 x pressure gauge with hoses and measuring connectors

- 2 x electric 4/3 directional valve

- 2 x manual 4/3 directional valve

- 1 x electric 4/2 directional valve

- 1 x manual 4/2 directional valve

- 2 x throttle check valve, sandwich version

- 2 x relief valve, sandwich version

- 2 x reducing valve, sandwich version

- 2 x throttle-check valve, in-line version

- 1 x check valve, in-line version

- 2 x check valve, in-line version

- 1 x flow divider, in-line version

- 12 x hydraulic hose with quick couplings

- 40 x electrical cable with 4 mm connectors

- A set of exemplary laboratory exercises

Test bench DMSD-02

Example configuration

- Mobile assembly table with a double-sided work area, equipped with a container with drawers, a panel for mounting electrical relays, a holder for hanging diagrams and a hanger for hydraulic hoses

- Pump unit with a variable displacement piston pump with a Load Sensing regulator, flow 11 l/min, a 230V, 50 Hz electric motor with a power of 2.2 kW, a pressure limiting valve and a solenoid valve for quick release of pressure from the system

- 25L oil tank with raturn line filter, breather, oil level indicator

- LS pressure regulator

- Electric control panel controlling the operation of the power supply with overload protection

- Panel meter for current, voltage and power

- Power supply DC panel

- Panel with set of electric relays

- Panel with electrical switches

- 2x pressure and temperature transducer CAN

- 1x flowmeter CAN

- 1x electronic measuring panel with the possibility of exporting data to a computer

- 2 x manifold branching the pressure and return line with a built-in manual relief valve

- 1x double-acting cylinder with variable load

- 2 x double-acting cylinder

- 4 x electric limit switch

- 1 x orbital motor

- 3x pressure gauge with test hose and coupling

- 2 x electric 4/3 directional valve

- 2 x manual 4/3 directional valve

- 1 x electric 4/2 directional valve

- 1 x manual 4/2 directional valve

- 2 x throttle check valve, sandwich version

- 2 x relief valve, sandwich version

- 2 x reducing valve, sandwich version

- 2 x throttle-check valve, in-line version

- 1 x check valve, in-line version

- 2 x check valve, in-line version

- 1 x flow divider, in-line version

- 12 x hydraulic hose with quick couplings

- 40 x electrical cable with 4 mm connectors

- A set of exemplary laboratory exercises